CemeCon´s hard ceramic PVD coatings contribute to raise the productivity in this area by enabling stable large scale production 24/7. Applied on tools, the coatings drastically reduce maintenance, cleaning, repairs and production stops through:

- protection against abrasive and adhesive wear

- preservation of the surface finish, polished or structured

- protection against corrosion and fretting

- improved demolding

- reduction or elimination of deposits

- reduction of the cycle time

- dry lubrication

allowing for a cleaner production of medical devices without the need for lubrication.

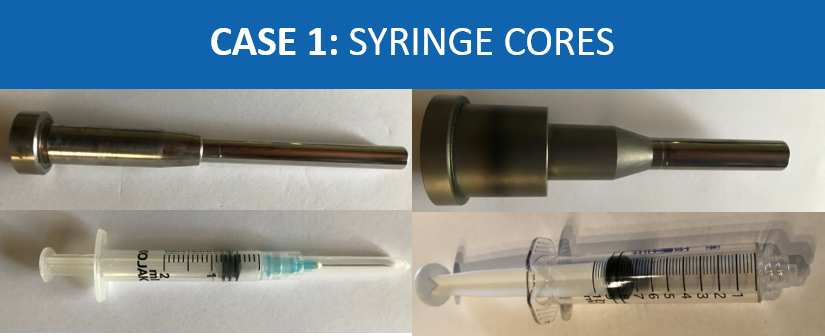

See two examples of coated tools below.

Syringe cores

Before coating

Parts sticking to the core, high demolding force, plastics deposits on the cores > scratches on the parts inner wall, frequent and difficult cleaning, wear and fretting on the conical part.

Coated with CCMold HyperSlip CrN

Demolding force reduced by up to 20%, less and easy to remove deposits, shorten cycles, no wear and fretting, less maintenance.

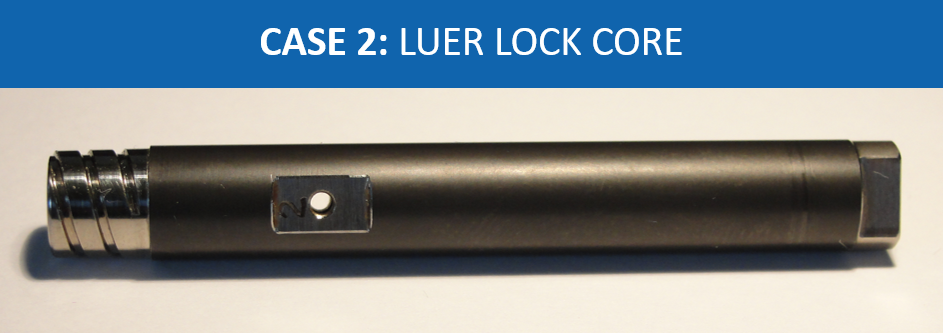

Luer lock core

Before coating

Sticking of parts to the core, high breakaway force, untrue thread, lint and hair formation, lubrication fat leaking into the cavities.

Coated with CCMold HyperSlip CrN on the thread and DLC on the shaft

Running completely dry, demolding forces reduced by up to 20%, round thread, no linting, no cleaning, no stops, faster production.