High-precision dimensional correction of tools with CCMold Correct

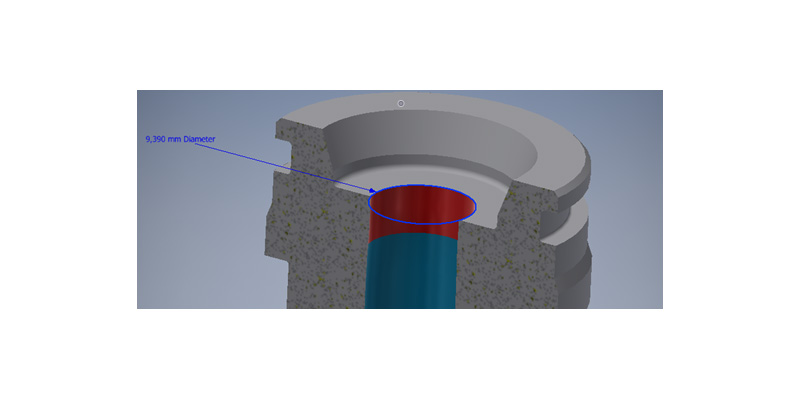

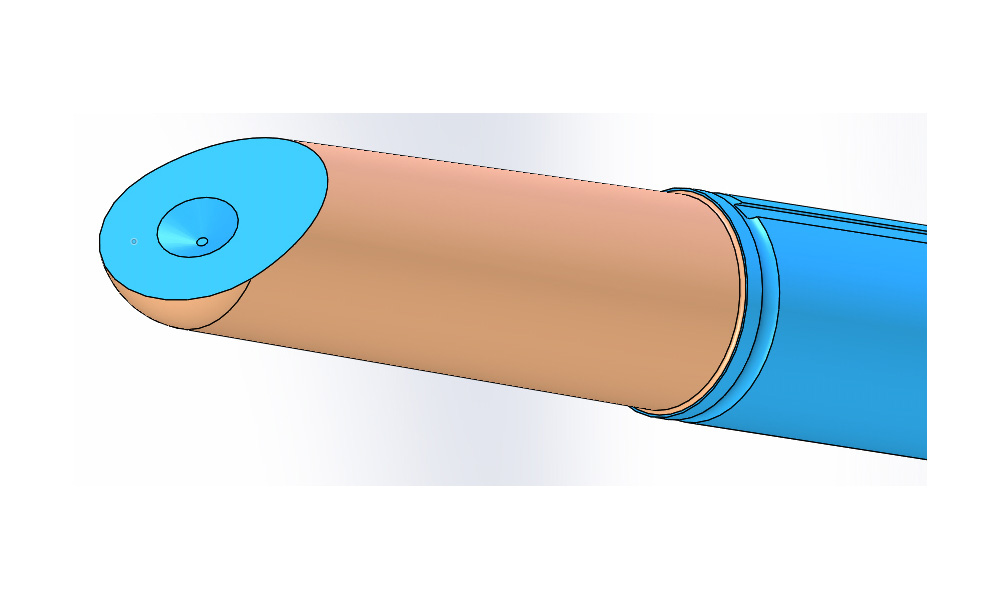

Our specially developed ceramic PVD coatings can be used for dimensional correction of tools. Tools can be coated completely or partially on selected areas in a desired thickness:

- without building up the edges

- without finishing

- at low temperature 170° C

- with a thickness of 1 µm to 40 µm

- with accuracy of up to ± 10%

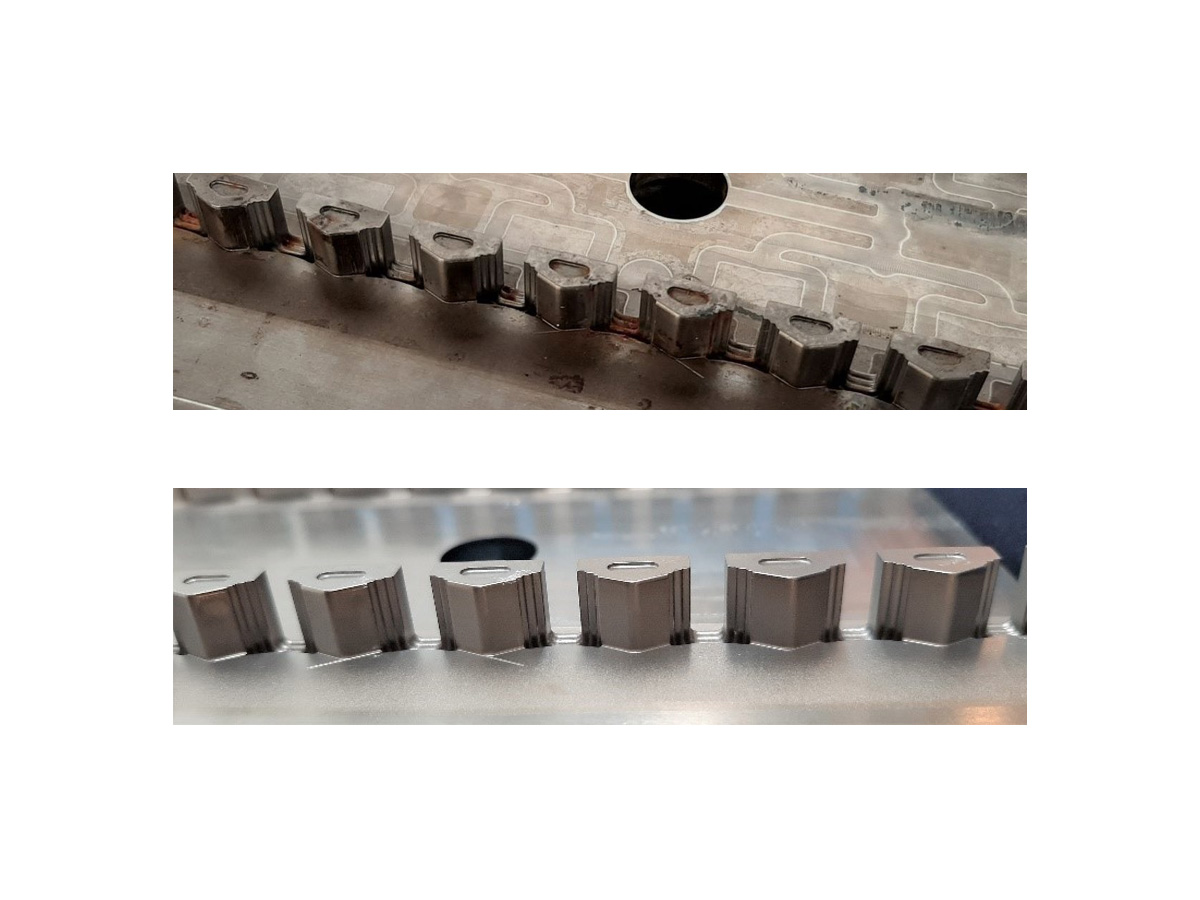

In this way, tool dimensions can be adjusted for corrections or finetuning processes. CCMold Correct coatings can also be used to eliminate burr formation or when repairing old worn tools. See examples below.